Why Automation is the future of Industrialisation

Industrial automation is the second step beyond mechanisation when we talk about industrialization. It is primarily the use of control systems, such as information technologies, robots and computers for handling different processes and machineries in an industry to displace manual work done by humans in day to day activities in a well controlled manner.

Automation in the industrial workplace provides the advantages of improving productivity and quality while reducing errors and waste, increasing safety, and adding flexibility to the manufacturing process. Industrial automation refers to the categorization of software and hardware and a mechanism that combines them (hardware & software). It also provides increased safety, reliability, and profitability. Many industries can benefit from industrial automation processes.

Depending on the operations involved, the industrial automation systems are majorly classified into two types, namely process plant automation and manufacturing automation. Some of the largest ones include manufacturing, oil and gas, paper mills, and steel mills. There are four factors that connect with each other in order to form an industrial automation system. They are Industrial Sensors and control devices, Human-machine interface (HMI), Programmable logic controller (PLC), Motor control units. Industrial Automation Systems are of different types, such as Fixed Automation (Hard automation), Programmable Automation, Flexible Automation and Integrated Automation.

The need for automation has proven to be fruitful with the passing of time. Automation can keep your process in-house, improve process control and significantly reduce lead times compared to outsourcing or going overseas. Automation solutions are based on your unique needs and goals and pay for themselves quickly due to lower operating costs, reduced lead times, increased output and more. It also involves the process of rolling out new features using advanced technology in business to reduce limitations. The numbers must be present in a simplified manner so that it becomes easier for the decision makers to make decisions.

While few organizations are still using the manual way of reporting data, many other industries have started using autonomous technology to see a change in the overall productivity. In short, manufacturing is a game of numbers which calculates how much we can produce with the limited resources at our disposal.

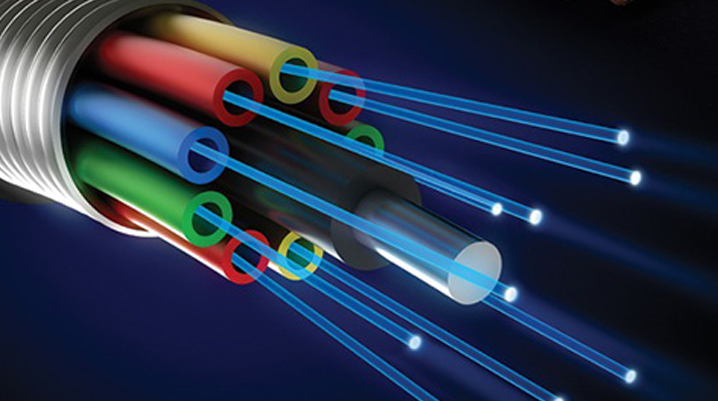

3C3 also provides industrial automation and various other structured cable solutions. Follow us on our social media channels including Facebook, Twitter, LinkedIn and Instagram.