The Importance And Choice Of Fiber Tools For System

Integrators

Com Core Connexions or 3C3 as we are now known is a one-stop

solution for various networking products. The company offers

totally integrated solutions to its clients and system

integrators, which helps them avoid approaching different

vendors and purchasing each component separately.

Our amazing range of products serves the networking needs of

various industries like Education, Information Technology, the

Government, and Hospitality, besides meeting the needs of

international clients in India for the Global innovation

center.

We provide a strong support base for system integrators. The

importance and usefulness of a systems integrator cannot be

undermined. As compared to offering expensive and unique

components, we believe in cost-effective and preconfigured

solutions

Various tools are required for the installation and maintenance

of networking products or their use in system integrators.

Why are fiber optic tools important?

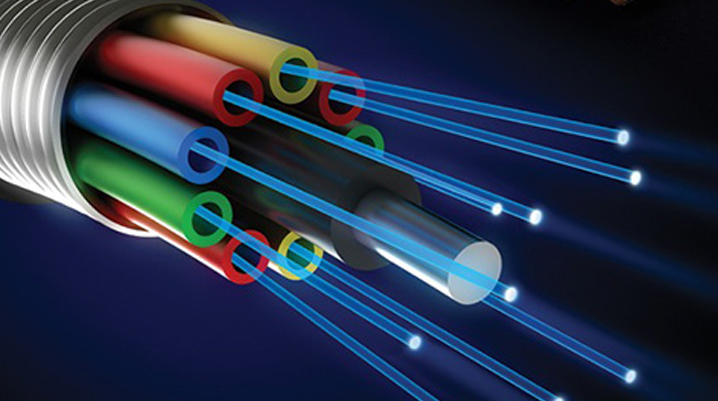

Tools are extremely important to install, maintain,

and troubleshoot networking products. Fiber optic networks are

extremely delicate and complex to install, maintain, and

troubleshoot. Specific tools need to be used which are meant for

a particular purpose to ensure fiber optic cables are not

damaged and high performance is achieved. There are different

procedures to be adapted in order to get effective results and

it is imperative to understand these basic, but golden rules, in

order to get the best results.

What are the different kinds of fiber optic tools for

testing and installation?

Splicing ToolsThere are fiber optics that need to be melted together, for

which splicing tools are required. There are different kinds of

splicing tools for fiber optics that are available in the

market. They are heat oven, fiber splice protection sleeves,

fusion splice, optic lever, and many others. Mechanical and

fusion splicing are the two kinds of splicing that can be done.

Two fiber ends of an optic cable are held together in order to

have a light pass from one fiber to another. This kind of

process is managed by mechanical tools. Infusion splicing, glass

ends of the fiber are fused or welded together to ensure that

there is a continuous connection and very little light is

lost

Fiber Inspection or Fiber Tools

Fiber tools are used for the production and troubleshooting of fiber

optics, to ensure that they work continuously and effectively.

There are various aspects of a cable that can be tested; the

amount of power that is being transmitted, breakages, and any

other aspect that needs to be checked. There are different kinds

of inspection tools that can be used and some of them are faulty

locators and optical identifiers.

Cleaning Tools

In order to transmit light without any obstruction,

it is important to ensure that the fiber cables are free from

dust, dirt, oil, and other constraints. The main areas that

require cleaning are connectors and ferrules. No cables should

be touched with bare or naked hands, in order to avoid

contamination and damaging of the cables. Alcohol and wipes are

the best materials to be used for cleaning.

The various kinds of Fiber Optic Tools offered by 3C3 and

their uses:

Splicing Machines

Splicing Machines like OFS-108, OFS-109, and Fiber

Splicing Tool Kits are used for high-speed fiber fusion.

Fiber Strippers and Fiber Jacket Strippers

These tools are used to remove the jacketing, from

1.6 mm to 3.0 mm. The coating is stripped to expose the fiber

cladding.

Cutters

There are two kinds of Cutters – Fiber Cable Yarn

Cutters and Fiber Tubing Cutters. Cutters are used to cut the

members inside the Fiber Jackets and the Metal Central Tube.

Fiber Optic Adapters

They are used to join two fiber optic patch cables

together and come with superior low loss performances and high

repeatability.

Slitters

Splicing Machines like OFS-108, OFS-109, and Fiber

Splicing Tool Kits are used for high-speed fiber fusion.

Splicing Machines

3C3 offers Universal Round Fiber Cable Slitters,

Armored Cable Slitters, and Longitudinal Cable Sheath Slitters

and is used for jacket removal of PE, PVC, and Rubber

High Precision Cleavers

They are used to cleave fibers quickly, easily, and

effectively and are a perfect aid to any field splicing

systems.

Features of Tools from 3C3 – Why choose us for your

Tools?

Our tools are used by several manufacturers across

various industries, thus making them flexible and

user-friendly.

The prices are so cost-effective that

customers are pleasantly surprised and delighted with their

effectiveness and the value-add that they bring to the

business.

These tools are designed in such a way that

they meet the challenges that new-age businesses demand.

The

material of the highest quality is used, thus making our tools

deliver excellent and consistent performance, anytime, every

time.

They are waterproof and moisture resistant and

hence they can be used, both indoors and outdoors.

When

a comparison is made with other products available in the

industry, we stand out from the competition for our

effectiveness and uniqueness.