Industry 4.0 represents the next phase of industrial transformation, is redefining the way industries operate by integrating cutting-edge technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), cloud computing, and automation. Smart factories are now becoming a reality where machines, systems, and humans seamlessly collaborate to make manufacturing smarter, faster, and more efficient.

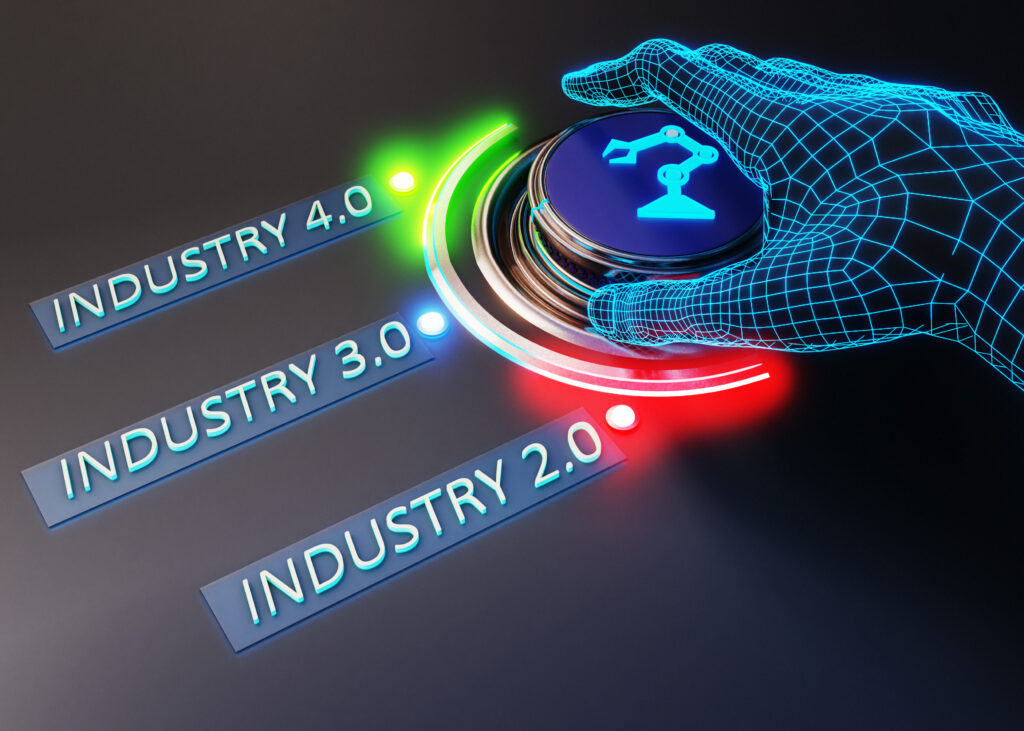

It’s a natural progression following the first three industrial revolutions:

Industry 1.0 – Mechanization using steam and water power.

Industry 2.0 – Mass production powered by electricity.

Industry 3.0 – Automation using electronics and IT.

Industry 4.0 – Cyber-physical systems, IoT, and smart automation.

At the heart of Industry 4.0 is data-driven decision-making. With real-time analytics, predictive maintenance, and connected systems, businesses can optimize operations, minimize downtime, and reduce costs. Imagine a system where machines alert operators about potential failures before they occur or where supply chains adjust dynamically to changing demands.

Adopting Industry 4.0 is no longer optional—it’s the key to staying competitive and future-ready. Industries such as manufacturing, logistics, energy, and even healthcare are already reaping its benefits. Whether it’s robotics, digital twins, or advanced automation, these technologies empower organizations to innovate and drive sustainable growth.

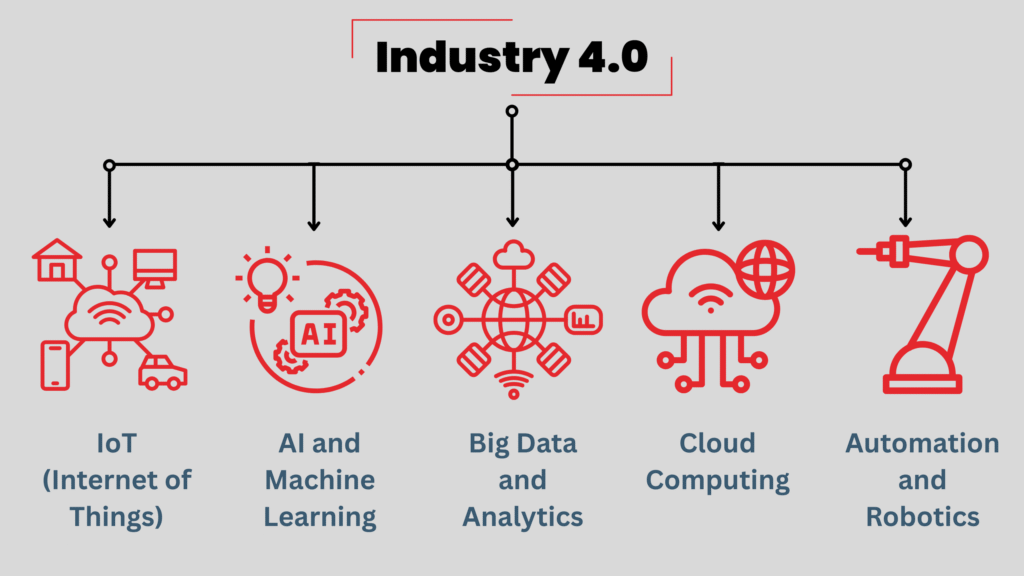

This transformation is enabled by technologies such as:

- IoT (Internet of Things): Connecting devices and systems.

- AI and Machine Learning: Data-driven insights and predictions.

- Big Data and Analytics: Making informed decisions using real-time data.

- Cloud Computing: Scalable storage and processing power.

- Automation and Robotics: Enhancing efficiency with minimal human intervention

Key Technologies Driving Industry 4.0

- Internet of Things (IoT): IoT enables machines and equipment to communicate in real time, sharing data seamlessly. Sensors attached to industrial equipment track metrics such as temperature, pressure, and performance. This technology enables predictive maintenance, saving significant costs and preventing downtimes.

- Artificial Intelligence (AI): AI enables machines to learn from data and improve their performance over time. AI algorithms can detect patterns, predict failures, automate decision-making, and optimize production processes. For example, AI-powered robots in assembly lines reduce human errors and increase output accuracy.

- Big Data and Analytics: Massive amounts of data are generated daily in manufacturing environments. Big Data tools analyze this information to derive valuable insights, driving informed decision-making. Real-time analytics ensure companies can adapt to challenges and opportunities quickly.

- Digital Twins: A digital twin is a virtual representation of a real-world asset or process. For instance, an automotive company can simulate vehicle performance in virtual environments before physical production. This reduces costs, improves performance, and minimizes risks.

- Cloud Computing: Cloud platforms offer scalable solutions for data storage and access, enabling global teams to collaborate in real time. With centralized control, companies can streamline their processes and improve efficiency.

- Cyber-Physical Systems (CPS): CPS integrates computer-based algorithms with physical processes, creating a digital bridge between the physical and virtual worlds. These systems improve accuracy and agility in manufacturing.

Why is Industry 4.0 Important?

Industry 4.0 revolutionizes industries by enabling organizations to:

- Enhance Operational Efficiency: By automating repetitive tasks, optimizing resource utilization, and eliminating bottlenecks, Industry 4.0 delivers significant productivity gains.

- Achieve Predictive Maintenance: Through real-time monitoring and AI-driven analysis, businesses can predict equipment failures, reducing unplanned downtime and repair costs.

- Improve Product Quality: Advanced technologies ensure precise manufacturing, reducing defects and waste. AI systems monitor production lines for quality assurance.

- Enable Customization and Flexibility: Smart factories allow businesses to adapt quickly to changing customer demands, enabling mass customization of products without compromising efficiency.

- Support Sustainability Initiatives: By optimizing resource usage, reducing energy consumption, and minimizing waste, Industry 4.0 promotes environmentally friendly practices.

- Boost Competitiveness: Organizations that adopt Industry 4.0 can react faster to market changes, increase profitability, and deliver better customer experiences.

Applications of Industry 4.0 Across Industries

- Manufacturing: Manufacturing is the heart of Industry 4.0, with smart factories leading the way. Robots perform repetitive tasks with high precision, while IoT-enabled sensors monitor performance and ensure quality control. Real-time analytics optimize production schedules, leading to reduced waste and better efficiency.

- Logistics and Supply Chain: Industry 4.0 revolutionizes logistics by enabling smart warehouses, automated inventory management, and predictive demand planning. IoT devices track shipments in real-time, improving delivery times and customer satisfaction.

- Energy and Utilities: The energy sector leverages Industry 4.0 for smarter energy grids, predictive maintenance of equipment, and resource optimization. Renewable energy sources are integrated seamlessly using AI and IoT systems.

- Healthcare: In healthcare, Industry 4.0 facilitates telemedicine, smart medical devices, and automated diagnostics. Digital twins allow doctors to test treatment plans virtually, ensuring better patient outcomes.

- Mining and Agriculture: IoT sensors in mining monitor environmental conditions and equipment performance, improving safety and efficiency. In agriculture, connected systems enable precision farming, resource management, and automated machinery.

Challenges of Adopting Industry 4.0

While Industry 4.0 promises significant advantages, it also comes with challenges:

- High Initial Costs: Implementing advanced technologies requires upfront investments in hardware, software, and training.

- Skills Gap: Employees need new skills to operate and manage Industry 4.0 systems. Training and upskilling are essential.

- Cybersecurity Risks: Connected devices and data flow increase the risk of cyberattacks. Businesses need robust security measures.

- Data Management: Handling large volumes of data requires proper infrastructure and storage systems.

- Integration Issues: Legacy systems may not easily integrate with new Industry 4.0 technologies.

The Future of Industry 4.0

As we move forward, Industry 4.0 will continue to evolve, bringing new opportunities and technologies:

- 5G Connectivity: The rollout of 5G will enable faster and more reliable communication, enhancing IoT capabilities and real-time monitoring.

- Edge Computing: Edge computing allows data to be processed closer to the source, improving response times and reducing reliance on cloud infrastructure.

- AI-Driven Innovations: AI will advance further, enabling autonomous factories where machines collaborate to complete tasks with minimal human intervention.

- Sustainable Manufacturing: With growing emphasis on sustainability, Industry 4.0 technologies will drive innovations to reduce carbon footprints and promote eco-friendly practices.

- Human-Machine Collaboration: Cobots (collaborative robots) will work alongside humans, augmenting their capabilities while ensuring safety and productivity.

How to Adopt Industry 4.0 in Your Business

- Assess Readiness: Evaluate your current systems and identify opportunities for digital transformation.

- Start Small: Begin with pilot projects, such as implementing IoT on a single production line, and scale gradually.

- Invest in Technology: Identify the right tools—IoT, AI, cloud computing—and integrate them with your existing infrastructure.

- Upskill Your Workforce: Provide training programs to ensure employees can adapt to new technologies.

- Focus on Cybersecurity: Protect your data with robust security systems and protocols.

- Collaborate with Experts: Partner with technology providers who can guide your Industry 4.0 journey.

Conclusion: Embracing the Revolution

Industry 4.0 is more than a trend it’s a paradigm shift that transforms how industries operate, innovate, and compete. By embracing technologies such as IoT, AI, robotics, and Big Data, businesses can unlock new opportunities, improve operational efficiency, and deliver unparalleled value to customers.

Organizations that act now to adopt Industry 4.0 will position themselves as leaders in the digital age. The journey may present challenges, but the rewards—efficiency, innovation, and sustainability—are undeniable.

The future is digital, connected, and intelligent. Are you ready to embrace Industry 4.0?