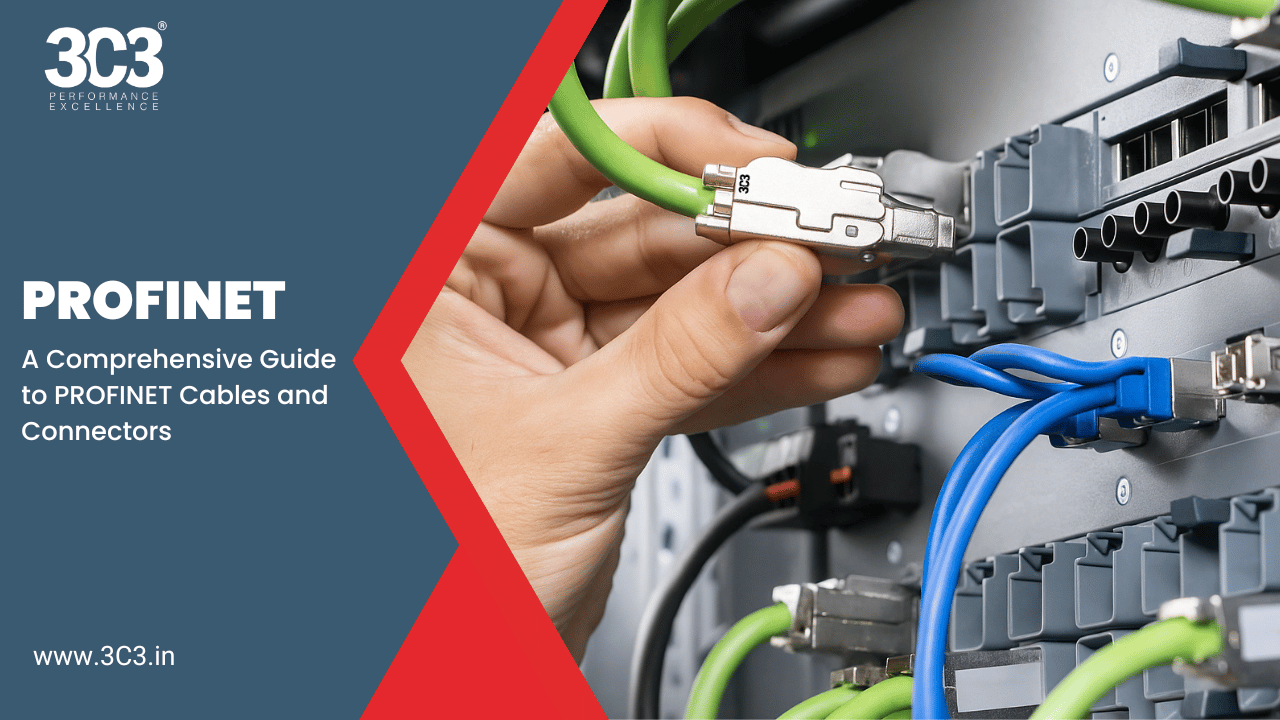

A Comprehensive Guide to PROFINET Cables and Connectors

In industrial automation, seamless communication between devices is essential for maintaining efficiency, productivity, and reliability. PROFINET, a globally recognized industrial Ethernet standard, plays a vital role in achieving this. However, the success of a PROFINET network depends heavily on the quality and compatibility of its cables and connectors. In this blog, we’ll explore the essentials of PROFINET cables and connectors, their types, and tips for choosing the right components.

What is PROFINET?

PROFINET (Process Field Network) is an Ethernet-based communication standard developed for industrial automation. It ensures high-speed, real-time data exchange between devices such as PLCs (Programmable Logic Controllers), sensors, and actuators, making it ideal for demanding industrial environments.

Importance of PROFINET Cables and Connectors

PROFINET cables and connectors form the backbone of a PROFINET network. They are specifically designed to:

- Handle high-speed and real-time data transmission.

- Withstand harsh industrial environments.

- Maintain reliable communication over long distances.

- Minimize network downtime and interference.

PROFINET Cables: Types and Features

PROFINET cables are categorized based on their application and environmental requirements:

- Type A (Fixed Installation)

- Designed for static installations where cables are not subject to movement.

- Typically used in control cabinets or fixed wiring setups.

- Type B (Flexible Installation)

- Suitable for environments where moderate bending or movement occurs.

- Commonly used for wiring between machinery and control systems.

- Type C (Highly Flexible)

- Built for continuous motion, such as in robotic arms or drag chains.

- Features enhanced shielding and durability to handle repetitive stress.

Key Features of PROFINET Cables:

- Shielding: Protects against electromagnetic interference (EMI) for stable communication.

- Twisted Pair Design: Ensures high-speed data transmission with minimal crosstalk.

- Temperature Resistance: Operates reliably in extreme industrial temperatures.

- Oil and Chemical Resistance: Withstands exposure to industrial substances

PROFINET Connectors: Types and Applications

PROFINET connectors ensure secure and reliable connections between devices in the network. Common types include:

- RJ45 Connectors

- Most commonly used in PROFINET networks.

- Easy to install with snap-in mechanisms.

- Ideal for indoor, less demanding environments.

- M12 Connectors

- Circular connectors with IP67 protection, designed for harsh environments.

- Common in outdoor setups and areas exposed to dust, water, or vibration.

- Hybrid Connectors

- Integrate data, power, and signal transmission into a single unit.

- Ideal for compact systems where space-saving is critical.

Factors to Consider When Choosing PROFINET Cables and Connectors

- Application Requirements:

- For static installations, use Type A cables.

- For robotic or dynamic systems, opt for Type C cables and M12 connectors.

- Environmental Conditions:

- Choose cables and connectors with appropriate IP ratings for protection against dust, water, and chemicals.

- Data Transmission Needs:

- Ensure components can handle the required bandwidth for your application.

- Durability and Longevity:

- Opt for certified PROFINET components to ensure compatibility and reliability

Installation Tips for PROFINET Cables and Connectors

- Plan the Layout: Avoid sharp bends and keep cables away from high-power lines to reduce interference.

- Use Proper Tools: Use certified crimping and installation tools for connectors.

- Test the Network: Perform diagnostic checks to ensure seamless communication.

- Regular Maintenance: Inspect cables and connectors periodically for signs of wear or damage.

Future Trends in PROFINET Cables and Connectors

As industrial systems evolve, so do the requirements for PROFINET components:

- Higher Data Rates: Supporting faster communication for Industry 4.0 applications.

- Miniaturization: Compact connectors and cables for smaller devices.

- Improved Durability: Enhanced materials for longer service life in extreme environments.

Conclusion

The performance and reliability of your PROFINET network depend on the quality of its cables and connectors. By understanding their types, features, and proper installation techniques, you can build a robust and efficient communication system.